5 Axis 3D printing

What is 5-Axis 3D Printing?

5-axis 3D printing, also known as 5D Printing, it is an advanced technology that allows you to print three-dimensional objects with great precision and detail, using a 3D printer with five axes of motion. This technology allows you to print complex objects with more complex geometries and smoother surfaces than traditional 3D printing.

5-axis 3D printing uses a 3D printer that can move along three Cartesian axes (x,y,z) and two rotational axes (a,b), allowing you to position the print head in precise positions and different angles. This means that the 3D printer can rotate the object while printing, allowing you to print more precisely and detailedly.

5-axis 3D printing is mainly used for the production of objects with complex geometries, such as aeronautical parts, customized prosthetics and industrial machinery parts. Thanks to its ability to print more precisely and detailedly, 5-axis 3D printing allows you to reduce production times and improve the quality of the final product.

In general, 5D Printing is an advanced technology that is revolutionizing the production of three-dimensional objects, allowing you to create objects with greater precision and detail and further improving the quality of the final product.

How a 5-Axis 3D Printer Works?

A 5-axis 3D printer using five axes of motion to print three-dimensional objects, allows greater precision and detail compared to a traditional 3D printer with only 3 axes.

The 5-axis 3D printer uses a 5D Printing head that can move along three Cartesian axes (x,y,z) and two rotational axes (a,b), allowing you to position the print head in precise positions and different angles.

The 5-axis 3D printing process begins with the preparation of the 3D model, which is created using CAD software or a 3D modeling application. The model is then loaded into the 5-axis 3D printer, where it is processed by the Slicing software, which breaks the model into thin layers and generates the G-code that drives the printhead.

Once the G-code has been generated, the 5-axis 3D printer starts printing the object, moving the print head along the five axes of movement.

While printing, The print head can be rotated and tilted for precise positioning and different angles, allowing you to print more precisely and detailedly.

The 5-axis 3D printer can use a wide range of 3D printing materials, including plastic, metallo, ceramics and resins. The choice of material depends on the application and the specific requirements of the final product.

La Stampa 3d a 5 Assi nell'Industria.

5-axis 3D printing is revolutionizing the industry in many different ways. Thanks to its ability to print three-dimensional objects with greater precision and detail than traditional 3D printing, 5-axis 3D printing is also used in many sectors of industry for the production of custom parts and components.

5-axis 3D printing is used to produce lightweight and strong aircraft parts, helping to reduce the weight of aircraft and improving fuel efficiency. The automotive industry also uses 5-axis 3D printing to produce customized replacement parts for vehicles, reducing production costs and improving delivery times. The medical industry uses 5-axis 3D printing to produce customized prosthetics and anatomical models for surgical planning.

In general, 5-axis 3D printing is revolutionizing manufacturing in many industry sectors and is expected to continue to do so in the future, helping to improve efficiency, the customization and sustainability of production. Furthermore, 5-axis 3D printing allows you to produce complex parts with greater precision and detail, which would be difficult or impossible to produce using traditional manufacturing methods.

La Stampa 3D a 5 Assi nell'Industria Aereospaziale

5-axis 3D printing is also revolutionizing the aerospace industry in many different ways. Thanks to its ability to print three-dimensional objects with greater precision and detail than traditional 3D printing, 5-axis 3D printing is used in many sectors of the aerospace industry for the production of technologically advanced parts and components.

In particular, 5-axis 3D printing is widely used for the production of lightweight and strong aircraft parts, helping to reduce the weight of aircraft and improving fuel efficiency. Thanks to 5-axis 3D printing, you can create parts with complex geometries and smooth surfaces, which would be difficult or impossible to produce using traditional manufacturing methods. This means that 5-axis 3D printing allows you to create high-precision parts that meet the standards required by the aerospace industry.

Furthermore, 5-axis 3D printing is also used for producing prototypes of parts and components, which allow designers to quickly test different design solutions and verify the functionality of prototypes before moving to mass production. This means that 5-axis 3D printing helps reduce product development time and improve the quality of the final product.

In general, 5-axis 3D printing is revolutionizing the approach to the production of parts and components even in the aerospace industry, allowing you to create parts with greater precision and detail and further improving the efficiency and sustainability of production.

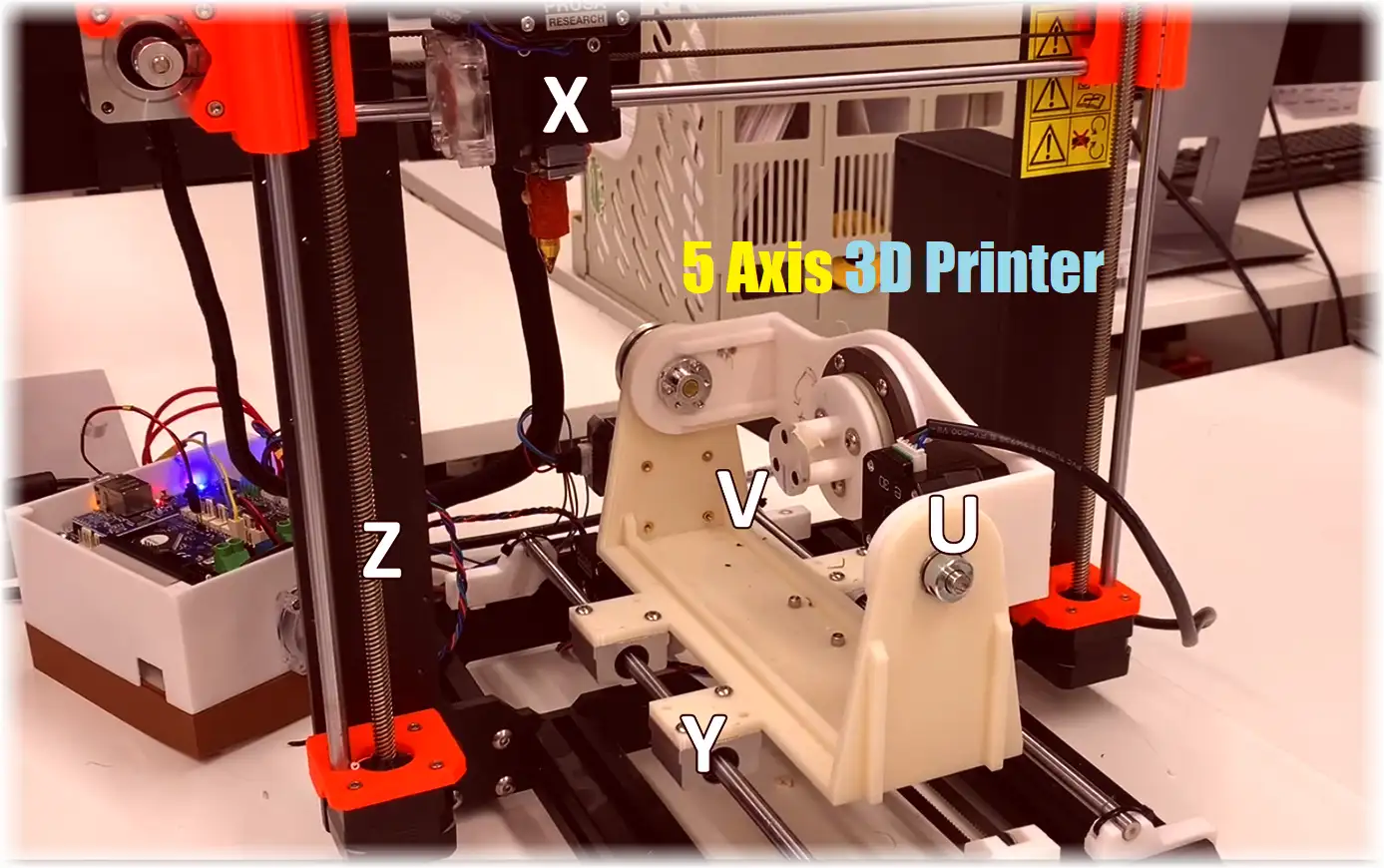

The Open5x 5-axis open-source 3D printer

Open5X is an open-source project that aims to create an affordable and accessible 5-axis 3D printer for all users. The Open5X 3D printer is based on a Prusa and Arduino platform, which controls the movements of the print head along the five axes of movement.

The Open5X 3D printer uses a five-axis system that allows you to rotate the object while printing, allowing you to print more precisely and detailedly. The Open5X 3D printer is compatible with a wide range of plastic filaments for 3D printing.

The Open5X project was developed to offer an affordable and accessible solution for 5-axis 3D printing, allowing anyone to create three-dimensional objects with greater precision and detail. The Open5X project it is open source, which means the source code and assembly instructions are available online and can be used by anyone to create their own 5-axis 3D printer.

In general, The Open5X 3D printer is an affordable and accessible solution for 5-axis 3D printing, which allows you to create three-dimensional objects with greater precision and detail than traditional 3D printing. The Open5X project has the potential to democratize 5-axis 3D printing, allowing anyone to access this advanced technology.