Supports in 3D Printing.

What are Supports in 3D Printing?

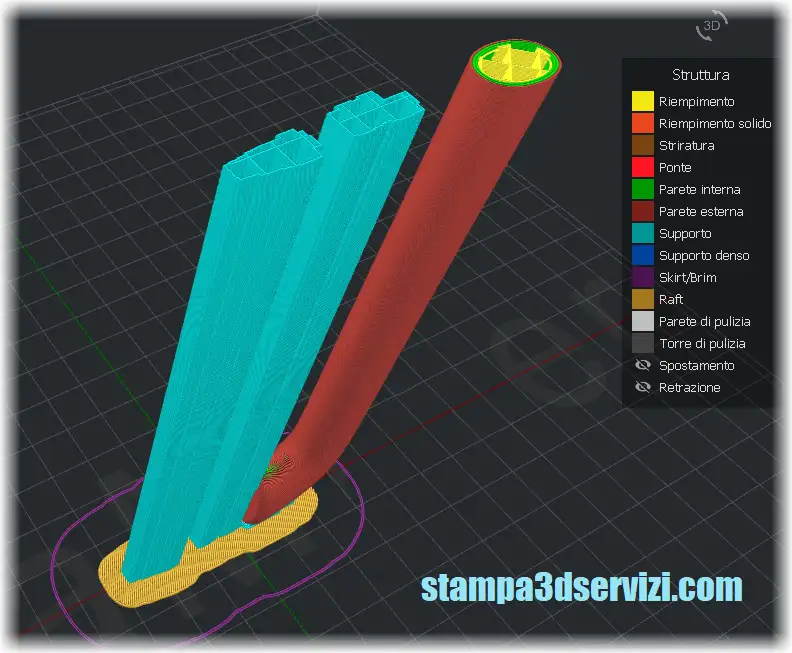

Supports in 3D printing are temporary structures that are generated during the printing process itself. The supports in practice are used to support the parts of complex objects where there are different surfaces with cantilevers that evolve with angles that are difficult to print, because they generally require to be supported by suitable structures during their construction.

In general, Supports in 3D printing are used to create parts with complex geometry or angles that are difficult to print, that require support during the printing process. Supports allow you to create three-dimensional objects with greater precision and detail, allowing you to create parts with complex geometries and smooth surfaces.

How Supports Are Created in 3D Printing?

During the 3D printing process, the printer head following the instructions in the print file, extrudes the material layer by layer, at the same time also creating the solid structures that create any supports where some of the parts of the object to be printed will rest.

Supports in 3D printing are created using the same material as the main part of the object and are carefully removed once printing is complete. Removing supports requires special care to avoid damaging the printed object.

When Supports Are Created in 3D Printing?

Support printing occurs when the object to be created has a complex geometry characterized by critical angles to print. So in this context the print head could without the presence of temporary support structures, may not be able to create the model correctly, as the extruded material would not find a solid surface where it could settle.

In general, i supporti sono necessari quando l’angolo di inclinazione del modello è superiore a 45 gradi rispetto alla piattaforma di stampa. For example, if you are printing a human figure with arms outstretched, supports may be needed to support your arms during the printing process. Furthermore, if you are printing a model with a complicated shape, such as a tower with sloping roofs, supports may be needed to support roofs during the printing process.

Supports are also used to prevent the phenomenon of “collapse” during the printing process. Collapse occurs when the print material warps due to excessive heating or being angled too steeply.. In this case, supports are used to support the part of the object that is collapsing, avoiding compromising the quality of the final product.

How Supports are Removed in 3D Printing?

Removing supports in 3D printing is an important step in the printing process, which requires special attention to avoid damaging the printed object. Supports are created using the same material as the main part of the object and are carefully removed once printing is complete.

Removing supports can be done manually using tools such as tweezers, thin-bladed wire cutters or knives. It is important to remove supports carefully to avoid damaging the printed object. Furthermore, it is important to remove all support residues so that they do not interfere with the functionality of the printed object.

In some cases, Removing supports can be made easier by using slicing software. Slicing software can generate supports “grilled” o “a nido d’ape”, which are easier to remove than traditional mounts.

Some printing materials, such as PLA, require fewer supports than other materials, such as ABS. Furthermore, the angle of inclination of the model can affect the amount of supports needed during the printing process.

In general, Removing supports in 3D printing requires special attention to avoid damaging the printed object. Removal of supports must be carried out with suitable tools and with precision, in order to guarantee the quality of the final product.

Soluble Supports in 3D Printing

Soluble supports in 3D printing are a type of supports that are used to support parts or components of the object during the printing process and which can be removed by immersing the object in a special solution that dissolves the support material.

Dissolvable supports are used to create parts with complex geometries or angles that are difficult to print, that require support during the printing process. Soluble supports are created using a soluble material, such as PVA or HIPS, which dissolves completely in water or in a specific solution.

Once printing is complete, the object is immersed in a solution of water or a solvent specific to the support material, which dissolves the supports without damaging the printed object. Removing soluble supports is simpler and less invasive than removing traditional supports, which may leave residue or damage the item during removal.

Soluble supports are mainly used in 3D printing of materials such as PLA, that require support during the printing process. However, it is important to consider that the use of soluble supports requires the use of a 3D printer with support for multiple filaments or a 3D printer with double extrusion.

In general, soluble supports in 3D printing are an effective solution for creating parts with complex geometries or angles that are difficult to print, allowing you to create three-dimensional objects with greater precision and detail.