The materials used in 3D printing

What are and what are the most used materials for online 3D printing.

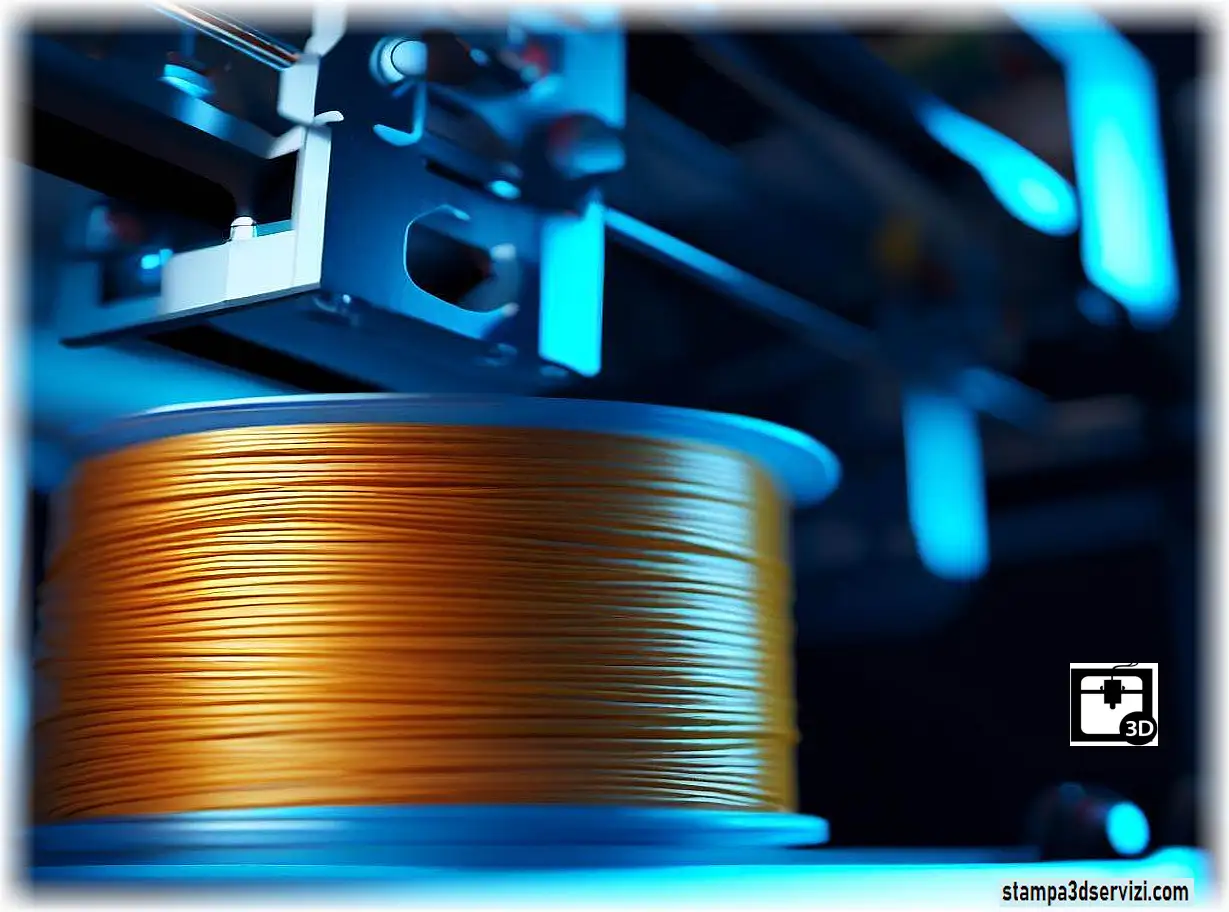

3D printing filaments are plastic polymers used in 3D FDM printers to create three -dimensional objects.

Today there are many materials for the creation of filaments for 3D online printing, each with its own properties and characteristics.

The filaments most commonly used in 3D printers FDM, they are the plane (polylactic acid) e l’ABS (styrene butadian acrylicitrile). The PLA is a biodegradable and ecological material, Easy to print and ideal for beginners. The ABS is more resistant and impact resistant, but requires a higher temperature for printing and can issue harmful vapors.

Other types of filaments include PETG (Ethilent Glycol Tereftolato), Il Nylon, he tpu (thermoplastic polyurethane) and polycarbonate. The PETG is resistant to water and UV rays, while the nylon is even more resistant and also flexible. The TPU, on the other hand, is ideal for printing flexible objects and polycarbonate is particularly resistant to shocks and also at high temperatures.

Because it is important to know how to choose the right filament for your 3D printing project.

It is important to know how to choose the right filament for your project based on the mechanical and thermal properties you are looking for.

In addition, It is necessary to make sure to use a high quality filament to avoid annoying problems during the same 3D printing, like the low quality of the printed object, The possible jam inception and the rapid degradation of the quality of the same finished object.

Technical filaments for 3D printing

The so -called technical filaments are more specialized filaments, designed for 3D printing of objects with specific properties, like resistance to high temperatures, flexibility or chemical resistance.

One of the most popular technical filaments is the peek (Polyetteconcetone), known for its high resistance to high temperatures and corrosion. However, The peek requires a specialized 3D printer capable of reaching very high temperatures and can be expensive.

Another technical filament is the Pei (polyethereimmide), known for its high chemical and thermal resistance. The PEI is often used in the production of resistant parts of wear and corrosion.

The carbon fiber filament is another type of popular technical filament, known for its high resistance and lightness. It is often used in the production of aeronautical and car parts.

Other technical filaments include PPSU (Polisolphone Polietersolphone), the TPC (thermoplastic copolymer), the sole (tereftalato di polyethylene), Il Pcabs (Polycarbonate/Acrylonitrile Butadiene Sirene) and reinforced nylon with glass fiber.

Choosing the right technical filament depends on the specific properties that are desired for the finished item. However, It is important to keep in mind that technical filaments can be more expensive than standard filaments and can request a specialized 3D printer.

How the filaments for 3D printing are produced.

3D printing filaments are produced using different techniques and materials depending on the application. Generally, The filament production process provides for the merger of plastic materials, such as ABS, the Pla and the pet-g, which are then extruded through a supply chain to create a continuous filament. The filament is then cooled and wrapped on a coil for distribution.

There are several techniques to produce 3D print filaments, including production by hot or cold extrusion, production by hot merger and production by means of double screw extrusion. In addition, There are also 3D printing materials based on metals and ceramics, which require production processes other than those of plastic materials.

Generally, The quality of 3D printing filaments is essential for the quality of 3D prints. The filaments must have a uniform diameter and a good adhesion between the different layers during printing. For this reason, 3D printing filaments manufacturers carry out rigorous quality controls on their products to ensure that they meet the required standards.

Filaments to produce casts with 3D printing.

Filaments to produce casts with 3D printing can be made using materials such as plaster, Cement or epoxy resin.

These materials are mixed with water or other chemicals to create a pasta and then extruded through a 3D printer. Once printed, Calci can be used to create objects in various materials, such as ceramic or metal.

Especially, The filaments to produce plaster casts are very common and are used for the production of architectural models, Prototypes of products and even for the production of artistic artifacts. The 3D printing of plaster casts allows you to create objects with high precision and very accurate details, reducing production times and improving the quality of the final result.

Generally, The production of casts by 3D printing is a constantly evolving technology and it is expected that it will become increasingly common in the future, thanks to its ability to create objects with high precision and the versatility of the materials used.